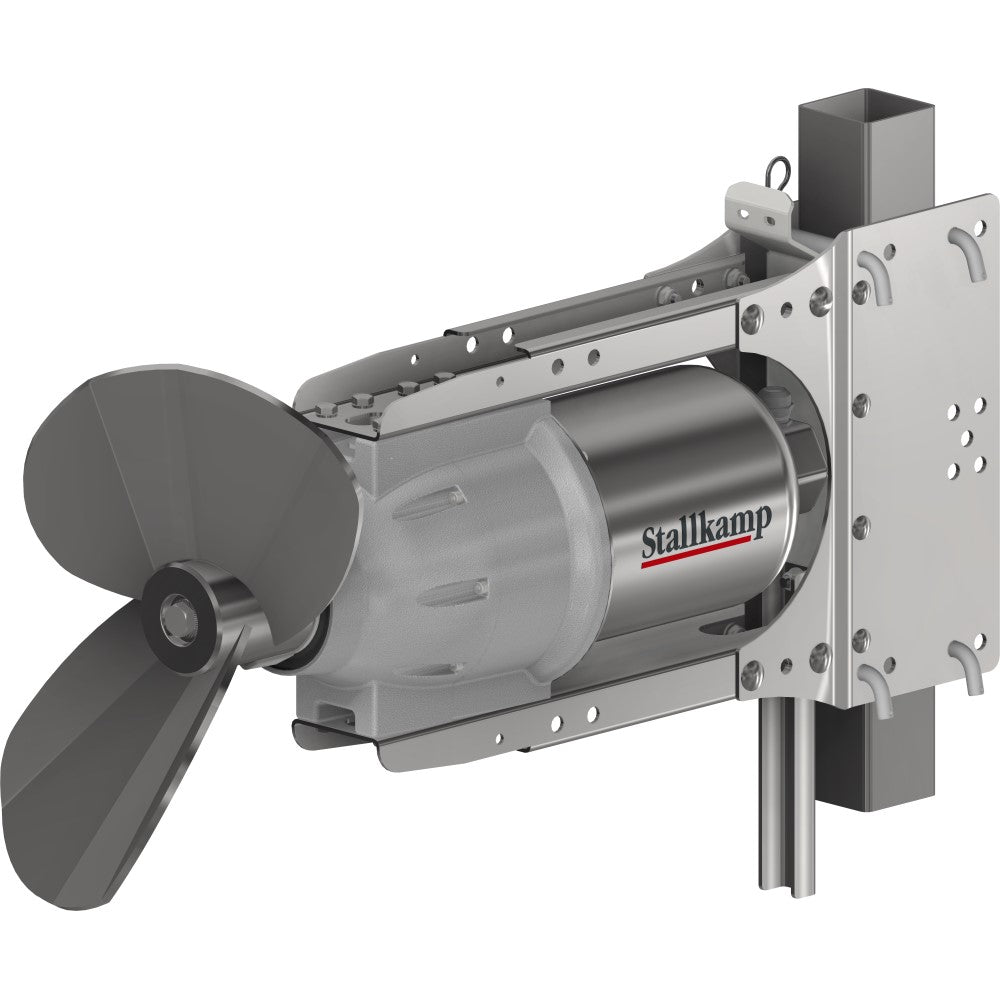

TMR 3i submersible motor mixer

Consultation appointment

Consultation appointment

Arrange a consultation appointment with one of our employees in the Neyer Forum or directly at your farm.

Price

Price

Contact us to find out the current price of the machine including your desired features.

delivery time

delivery time

Neyer Landtechnik has a variety of storage machines on site in the Neyer Forum Bad Waldsee - Mennisweiler. Contact us to find out the delivery time of your desired product.

A dealer

A dealer

Neyer Landtechnik is a certified A dealer for the brand and purchases this product directly from the manufacturer.

Benefit from the best conditions and our many years of expertise.

- Electric motors 11.0–22.0 kW

- Three-phase motors 400 V, 50 Hz, 1450 rpm.

- Protection class IP 68 / insulation class F=155 °C

- Thermal monitoring for each phase as overheating protection

- Motor housing made of stainless steel V4A 1.4404

- Gearbox housing and motor cover made of cast stainless steel (Ni-Resist material)

- Planetary gear

- Propeller speed 373 rpm

- Sealing: highly wear-resistant mechanical seal as standard

- Electric cable with cast screw connection, with swelling bodies in the longitudinal direction of the cable as moisture protection, special PU outer sheathing

- Sliding guide with depth stop made of V2A 1.4301 including adjustment option: 7° swivel up, 7° swivel down

- Stirring blade version made of stainless steel V2A 1.4301

The agitator is intended for the following applications:

- Stirring or homogenizing slurry in repositories, feedlots and slurry channels

- Stirring or homogenizing biomass in biogas plants or as part of waste fermentation processes

- Stirring or homogenizing industrial wastewater in industrial plants

- The agitator is designed for a variety of applications where a high flow rate is required in relation to the power consumption

- Basically, the stirring effect depends on the density and viscosity of the liquid as well as the contents and shape of the container. Larger containers may require more than one agitator.

- The agitator is designed for mixing liquids with variable pH values, generally from pH 5.3 - pH 8.1 at room temperature 20 °C. However, the relationship between pH value, temperature and chemical composition of the medium must always be taken into account.

Advantages:

- Immersion depth individually adjustable

- Liquid jet and flow direction can be adjusted as required

- High stirring performance

- Environmentally friendly and economical work

- Optimal homogenization of the media

- Good value for money

- High quality from our own production

- Diverse range of accessories

Ich helfe gerne

Ansprechpartner

Philipp GreinerVerkaufsleiter Farmtechnik